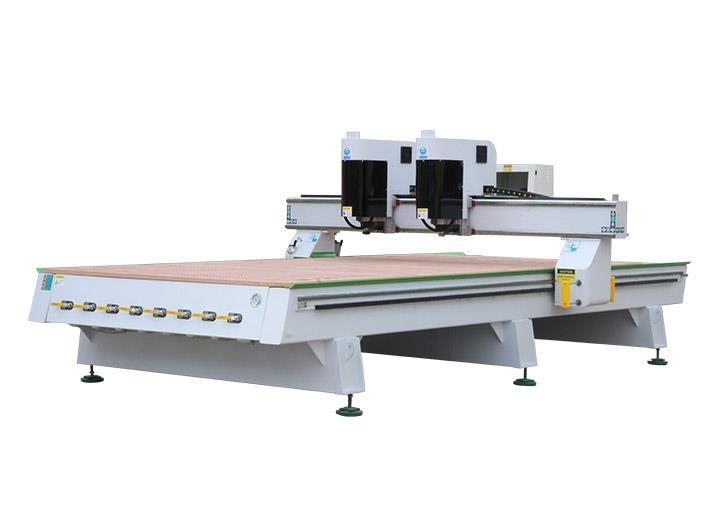

Machine CNC BCM1325A-Plus :

Application : Woodworking,letter Cutting,door making, furniture making,Electronic industry

Certificate : CE,ISO

Voltage :220V/1P/50HZ,380V/3P/50HZ,

Customized :Size Can be customized

- Description

- Advantage

- Specifications

Description

| ● Working area: 1300*2500*200mm|4′*8′ |

|---|

| ● CE standard |

| ● 3.0kw water cooling spindle(Option: 5.5kw,6.0kw ,7.5kw Quick-Release Spindle) |

| ● Heavy duty frame |

| ● Active safety system |

| ● X ,Y axis gear transmission, Z axis Taiwan TBI ball screw transmission |

| ● Taiwan Hiwin 20 rails |

| ● Vacuum table+T-solt |

| ● Schneider Electronic spare parts |

| ● Lubrication system |

| ● Rich auto A11 control system |

| ● Japan Omron limit switch |

| ● High torque stepper motor and drivers |

| ● Chinese fuling Inverter 3.7kw |

| ● 3.0kw double dust collector +Dust collector pipe+Dust collector support |

| ● Tool height sensor |

| ● Standard box of tools |

Advantage

| ▄ BCM A-Plus SERIES A low-cost, entry level BCAM CNC Router |

|---|

| ▄ High-quality components |

| ▄ International sales and service(7*24h) |

| ▄ Ideal for small shops or first-time CNC users |

| ▄ Primary Applications: Signmaking, General Woodworking, Exhibition Stands, Point of Purchase, Scenery & Sets, Solid Surface, Interiors, Foam Packaging |

|

|

Safety protection system: BCM1325A-Plus router inherits the safety protection system unique to BCAM products and provides external emergency stop function for equipment users. This function can protect effectively the personal safety of the equipment users, meet the European safety CE standards, and is very popular among users. |

| Control system:BCM1325A-Plus router control system is famous DSP A11 which is simple and easy to operate, the system has a wide range of support documents, power-off continuous carving, 2D 3D relief and other functions, easy to operate, widely used. |  |

|

|

|

Rail device:BCM1325A-Plus router rail system adopts Taiwan’s HIWIN high-quality rail. This guide rail makes BCM1325A-Plus work more accurately. The high quality pulley quality and excellent dustproof system also make BCAMCNC equipment last longer. |

| Spindle system:BCM1325A-Plus router selects Italian HSD air-cooling spindle, power range: 3.0KW-7.5KW.Tools change hoose from manual, quick-release, high-power and high-speed spindles for optimum processing of rigid sheet materials. |  |

|

Specifications

| Parameters | Standard Specifications BCM1325A Plus | |

|---|---|---|

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft | |

| Optional Working Area | 1300*1300*200mm|4*4ft | |

| Optional Working Area | 1500*3000*200mm|5*10ft | |

| Optional Working Area | 2000*3000*200mm|6*10ft | |

| Optional Working Area | 2000*4000*200mm|6*13ft | |

| Optional Working Area | 2000*6000*200mm|6*20ftth> | |

| Spindle Power | 3.0kw water cooling spindle | |

| X,Y,Z Traveling Positioning Accuracy |  0.05/2000mm 0.05/2000mm |

|

| Table Surface | Vacuum table+T-solt table | |

| X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBI Ball Screw | |

| Max. Rapid Travel Rate | 30m/min | |

| Max. Working Speed | 25m/min | |

| Cutting thickness | According materials | |

| Spindle Speed | 6000-24000RPM | |

| Drive Motors | Leadshine stepper motor and drivers | |

| Working Voltage | 380V(220v)/3 phase/28amp or 220v/ Single Phase/32amp | |

| Command Language | G Code | |

| Operating System | Richauto A11 DSP control system | |

| Interface | USB | |

| Software Compatibility | Option:BCAMPRO/VCarve/VCarve Pro/ArtCAM/UCANCAM,etc. | |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 5%~75% |

Reviews

There are no reviews yet.