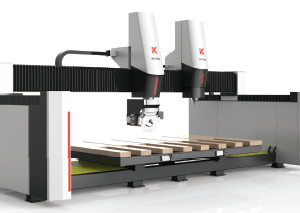

The five-axis bridge cutting machine :

The 5-axis CNC bridge saw is a sophisticated stone processing machine designed for automatic machining. It seamlessly completes the shaping of complex, five-sided surfaces through precise five-axis linkage control, utilizing three linear moving axes and two rotating axes. Tailored by IGOLDENCNC to meet the diverse cutting requirements of stone fabrication, it offers various processing modes including cutting, milling, engraving, and drilling. This bridge saw stands out for its multifunctionality, compact footprint, user-friendly operation, precise cutting capabilities, and seamless function conversion, making it an essential tool for stone machining manufacturers.

1. One machine with multiple functions, flexible five axes.

2. Simple operation and accurate processing.

3. Automatic measurement and intelligent import.

4. Real-time networking and remote control.

5. Automatic suction cup to move the plate and avoid saw marks.

6. Photo typesetting, on-demand pattern cutting.

- Description

- Advantage

- Specifications

Description

| Model | IK 5AXIS 500 | IK 5AXIS 700 | |

| Travel | X-Axis travel(mm) | 3200 | 3500 |

| Y-Axis travel(mm) | 2000 | 2000 | |

| Z-Axis travel(mm) | 400 | 500 | |

| A-Axis travel(‘’) | 0-90(Automatic) | 0-90(automatic) | |

| Z-Axis travel(‘’) | ±365 | ±365 | |

| Configuration | Fast travel speed (m/min) | 20 | 20 |

| Spindle speed (KW) | 18.5 | 22 | |

| Spindle motor speed (rpm) | 0-4500 | 0-5000 | |

| Saw blade diametre (mm) | 350-500 | 350-700 | |

| Workbench tilting degree (‘’) | 0-85 | 0-85 | |

| Total power (kw) | = 24 | = 35 | |

| Machine Weight (kg) | 4500 | 5800 | |

| Overall dimantions (mm) | 6200X3300X3000 | 6500X3300X3300 | |

| Functional configuration | Camera function | optional | Basic configuration |

| Vaccum manipulator system | optional | X | |

| Water damper | optional | optional | |

| Trepanning motor (7.5kw) | optional | X | |

Cutting and blanking/special-shaped cutting

and profiling function

Software Features

Advantage

| 1.BCAM S stone engraving machineOn the BCAM S stone CNC milling machine, we have created the most advanced equipment to handle various customized stone solutions. Our professional team can help you upgrade customized stone processing equipment with the accuracy of 3-axis and 5-axis CNC engraving machines.

Explore the functions and advantages of one of our CNC routers, and learn how to provide customers with customized parts to reduce costs and delivery time. |

|---|

| 2.Explore the functions and advantages of one of our CNC routers, and learn how to provide customers with customized parts to reduce costs and delivery time.The function of BCAM S stone CNC milling machine

These innovative machines can move on 2 axes (optionally 3 and 5 axes), so they can create the most complex shapes and shapes. The covering layer of the rubber pad allows you to handle the material without any surface scratches or excessive friction. A 1-inch water pipe will cool the blade during cutting to prevent excessive displacement. When the saw blade passes through your stone or other countertop materials, it can also cut at a fast speed. |

| 3. Benefits of BCAM S StoneChoose the leading S Stone CNC milling machine, which is an advanced machine that can quickly transform a blank into many amazing stone products. time. Before discovering how to order now, please explore the other great advantages of this saw. |

| 4.Application of CNC milling machineOur stone CNC milling machines are specially designed for stone cutting, but the functions of these dynamic machines are much more than that. Many other planers can also cut wood, steel, corrugated cardboard and plastic. Thanks to the unique core bit and water cooling system, our stone milling machine is most suitable for countertop materials.

Whether you are a custom cabinet manufacturer or a licensed construction company, stone processing CNC milling machines are an excellent investment for creating your own custom pieces. BCAM Pure is an environmentally friendly water filtration system that can be used directly with your CNC milling machine. Robot lifts, jib cranes or other equipment in our factory can take your production line to the next level. |

|

|

1.Choose the leading S Stone CNC milling machine, which is an advanced machine that can quickly transform a blank into many amazing stone products. time. Before discovering how to order now, please explore the other great advantages of this saw. |

| 2.Italy HSD 13KW water cooling spindle , HSK-63F ,with Water cooling tools functions |  |

|

|

|

3. 8 Pcs Linear Tools functions and HSK-63F tools holders |

| 4.Tool senser (Automatic tool calibration pad) allows easy and accurate “Z” zero position for single and multiple tool changes through the program. This can automatically measure the distance between the tool head and the material. |  |

|

|

|

5.Our S stone cabinet lines include both frameless access construction and traditional framed inset cabinets made to your specifications.

Also make perfectly for laundry rooms, home offices and other residential design projects. |

| 6.World-class servo motor and driving system ensures machine to run with fast speed and low noise |  |

|

Specifications

| Parameters | Standard Specifications BCS1325 | |

|---|---|---|

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft | |

| Optional Working Area | 1300*1300*200mm|4*4ft | |

| Optional Working Area | 1500*3000*200mm|5*10ft | |

| Optional Working Area | 2000*3000*200mm|6*10ft | |

| Optional Working Area | 2000*4000*200mm|6*13ft | |

| Optional Working Area | 2000*6000*200mm|6*20ft | |

| Spindle Power | Italy HSD 13kw(optional 15kw 18kw ) water cooling spindle | |

| X,Y,Z Traveling Positioning Accuracy |  0.02/2000mm 0.02/2000mm |

|

| Table Surface | T-solt table or Vacuum Cup table | |

| X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBI Ball Screw | |

| Max. Rapid Travel Rate | 30m/min | |

| Max. Working Speed | 20m/min | |

| Cutting thickness | According materials | |

| Spindle Speed | 6000-24000RPM | |

| Drive Motors | 4 sets 1500W Japan Servo motor and drivers | |

| Working Voltage | AC380v/50HZ/3 phase | |

| Command Language | G Code | |

| Operating System | Taiwan Syntec control system | |

| Interface | USB | |

| Software Compatibility | Option:Type3/Ucancam/Artcam/Solidworks,etc. | |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 60%~90% |

Reviews

There are no reviews yet.